It looks like my last thread got lost in the great purge. So I'll post up some of the old stuff and some new. As a refresher, this is not meant to be a full instruction on NFA construction, laws or machining for that matter. I am not a professional, these are just the methods I have found to work for me. Any suggestions on how to improve the process are always welcome. As for the NFA stuff. KNOW YOUR LAWS!. Plenty of online material to learn about making a form 1 suppressor. Its fun and can done by the very skilled all the way down to those who find a can opener challenging. I've seen and heard some great results from the freeze plug can guys. I myself have just enough skills to be dangerous to myself and wallet, so I have been going for more advanced methods. My only real machining advice is this. Research your material, goals, and machine. Measure, measure, measure. And know that sometimes you will go through 2-3 hours of setup to complete a 30 second milling operation. Especially if you are using an old school hand machine.

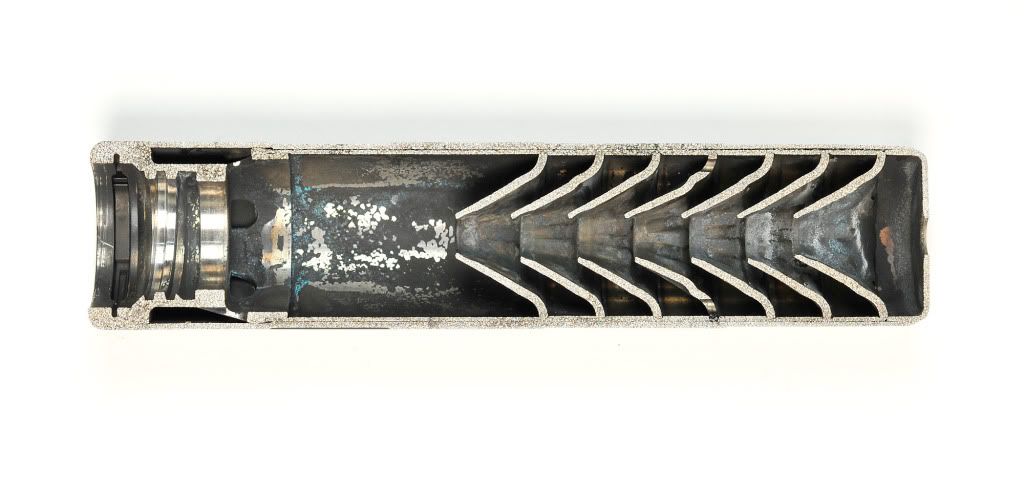

If you recall. My previous form 1 was a 8" 308 can with. Goals were decent suppression, low weight and QD ability. Below is a crude representation of how I machined the cones. As for the suppressor body, it was simply a process of turning and threading a tube. Lotsa instructions on the interwebs on how to do that. The first set of cones were out of 410 Stainless if I remember right. Fair machinability, gotta watch it a little. The tube is TI grade 9 with matching endcaps. Rear cap was made for a Griffin Taper Mount Flash Hider. Found the specs on Silencertalk and took alot of measurements myself. Spacer material used was 2024 AL. Again, The spacers are structural for alignment, about the only issue is possible wear from jetting, but I'll keep a look on it.

There she is sitting on my SCAR 17. I'd call it hearing safe, 12.9 OZ and QD, so all my goals were a success. (Flash hider adds 2.5 OZ) Since then, I've cut down the barrel to 14.1 and pinned/ welded the FH, chopped down the MI extension some more and Kryloned the whole enchilada. Super handy battle rifle now. Ordered up some gas jets to tune the system a little since the barrel chop. Will play with that when they come in.

Reply With Quote

Reply With Quote